Our Products

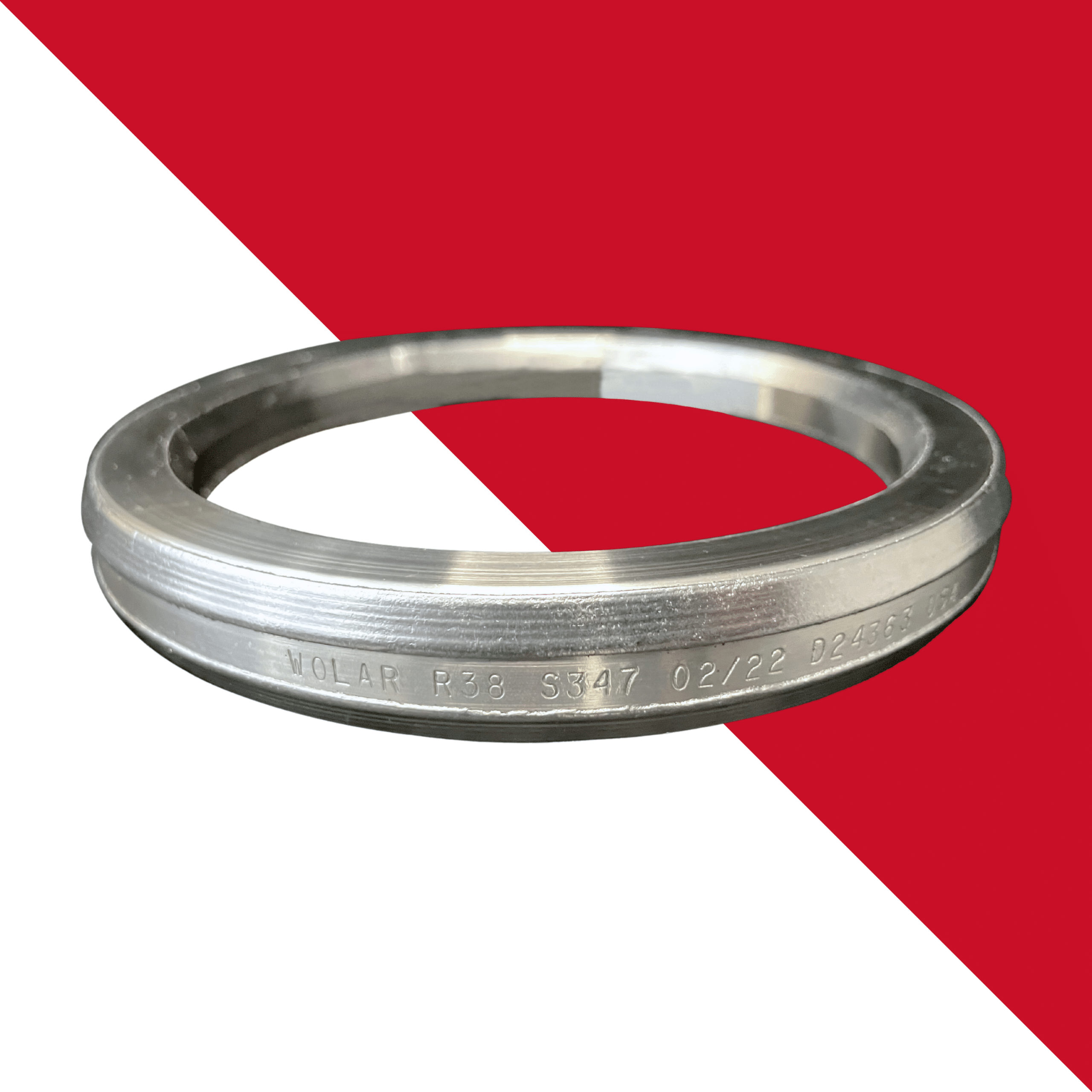

Ring Joint Gaskets

Ring Joint Gaskets, tailored for high-pressure (up to 5,000 psi) and high-temperature sealing environments, are meticulously engineered for reliability. Crafted to conform with API 6A and ASME B16.20 standards, these gaskets ensure full traceability and are available in oval or octagonal cross-sections to adapt to various flange designs. Manufactured from a wide spectrum of materials ranging from Soft Iron to exotic alloys like Hastelloy and Inconel and available with multiple plating options, they offer the versatility and performance needed across the oilfield and refining sectors.

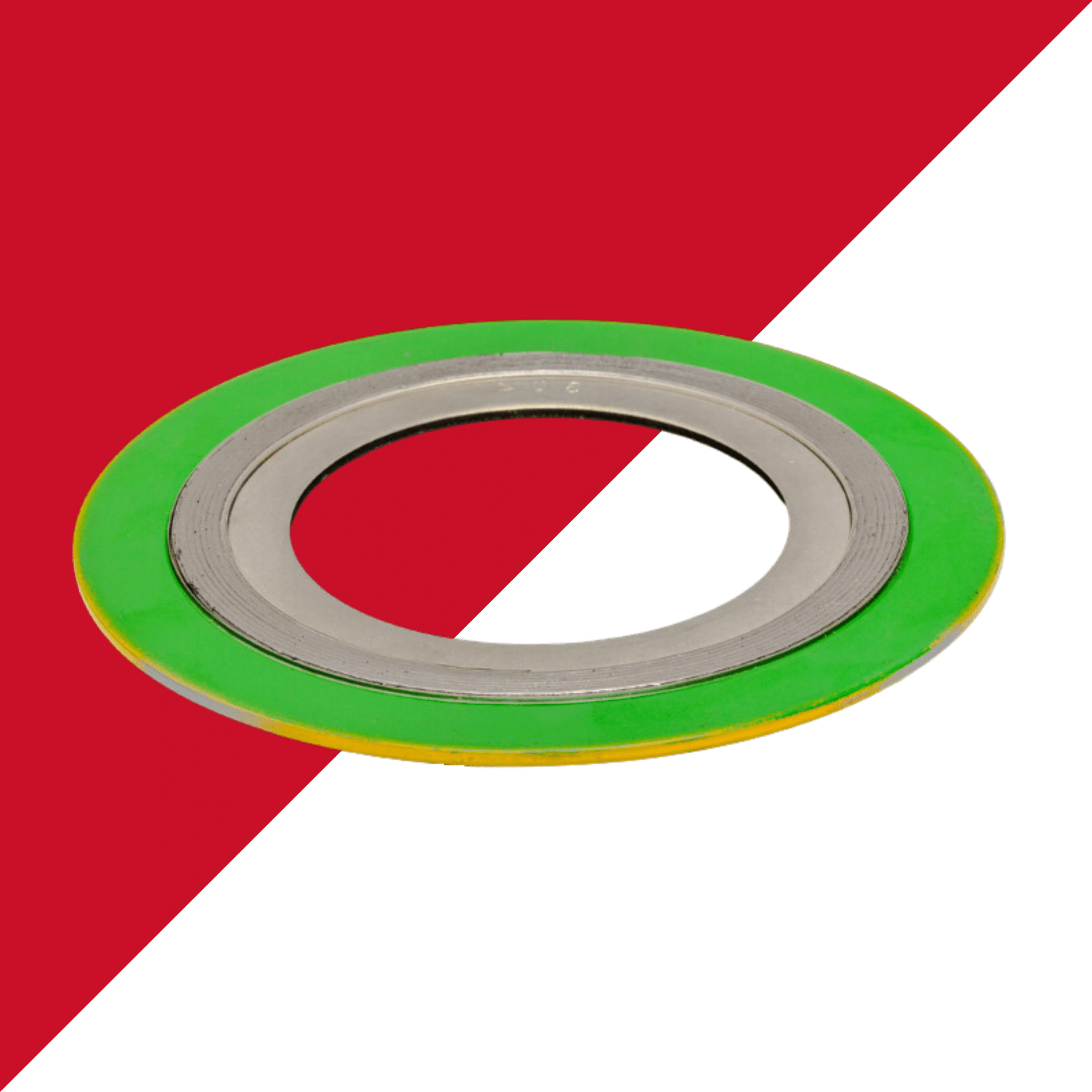

Spiral-Wound Gaskets

Spiral-Wound Gaskets, with a century of history, have evolved to become the primary choice for sealing across challenging applications, adhering to ASME B16.20 standards. These gaskets feature a unique construction comprising V-shaped metal windings and flexible graphite filler, secured by an outer guide ring. This design, augmented by an optional inner ring for improved sealing integrity, is available in materials like 304SS and 316SS, ensuring a durable, effective seal for raised-face flanges. Wolar’s offerings cater to various industrial needs, embodying innovation in complex sealing solutions.

K-RTJ

Kam Gaskets redefines the landscape of RTJ sealing, leveraging advanced engineering to offer unmatched sealing efficiency in rigorous applications. The core – an octagonal RTJ configured according to ASME and API standards – is complemented by serrated sealing surfaces lined with APX-2® graphite. This innovation ensures superior sealing at significantly lower stresses than conventional RTJs, backed by third-party validation. Designed for resilience, with a wide array of core materials and fire-safe features, these gaskets target high-demand scenarios from heat exchangers to imperfect flange surfaces, underscoring Wolar’s commitment to next-generation sealing solutions.